When it comes to industrial piping systems, choosing the right valve can significantly impact the efficiency and reliability of your operations. Gate valves and ball valves are two of the most popular types of valves used in various industries. Understanding the differences between gate valve vs ball valve is crucial to ensure you make the best decision for your specific application. In this article, we will explore the features, advantages, and disadvantages of both valve types to help you choose the perfect option for your needs.

Valves play a vital role in controlling the flow of fluids in piping systems. Whether you're dealing with water, oil, gas, or other substances, selecting the appropriate valve is essential for maintaining safety, reducing maintenance costs, and optimizing performance. Both gate valves and ball valves have their unique characteristics that make them suitable for different applications.

As we delve deeper into the comparison of gate valve vs ball valve, we will explore various aspects such as design, functionality, material, cost, and maintenance requirements. By the end of this article, you will have a clear understanding of which valve type is best suited for your specific needs. Let's get started!

Read also:Nolins Bar And Grille Reviews A Comprehensive Guide To Your Perfect Dining Experience

Table of Contents

- Introduction to Gate Valve and Ball Valve

- Design Differences Between Gate Valve vs Ball Valve

- Functionality and Operation

- Materials and Durability

- Cost Comparison

- Applications and Industries

- Maintenance Requirements

- Performance Metrics

- Longevity and Reliability

- Conclusion and Final Thoughts

Introduction to Gate Valve and Ball Valve

Gate valves and ball valves are both widely used in industrial applications, but they serve different purposes and operate in distinct ways. A gate valve, also known as a sluice valve, is primarily designed for on/off service, while a ball valve is known for its quick shutoff capabilities. Understanding their fundamental differences is the first step in determining which valve is ideal for your project.

Key Features of Gate Valves

Gate valves are characterized by their ability to provide a straight-through flow path, making them suitable for applications where minimal pressure drop is desired. They are typically used in larger pipelines and are ideal for infrequent operations. Some key features of gate valves include:

- Designed for full open or full closed positions

- Provides a straight-through flow path

- Available in various materials, including stainless steel, bronze, and cast iron

Key Features of Ball Valves

Ball valves, on the other hand, are known for their quarter-turn operation and quick shutoff capabilities. They are highly reliable and are often used in applications where rapid control is necessary. Key features of ball valves include:

- Quarter-turn operation for quick shutoff

- Compact design for space-saving installations

- Available in a variety of materials, including brass, stainless steel, and PVC

Design Differences Between Gate Valve vs Ball Valve

The design of a valve plays a significant role in its performance and suitability for specific applications. Let's examine the structural differences between gate valves and ball valves.

Gate Valve Design

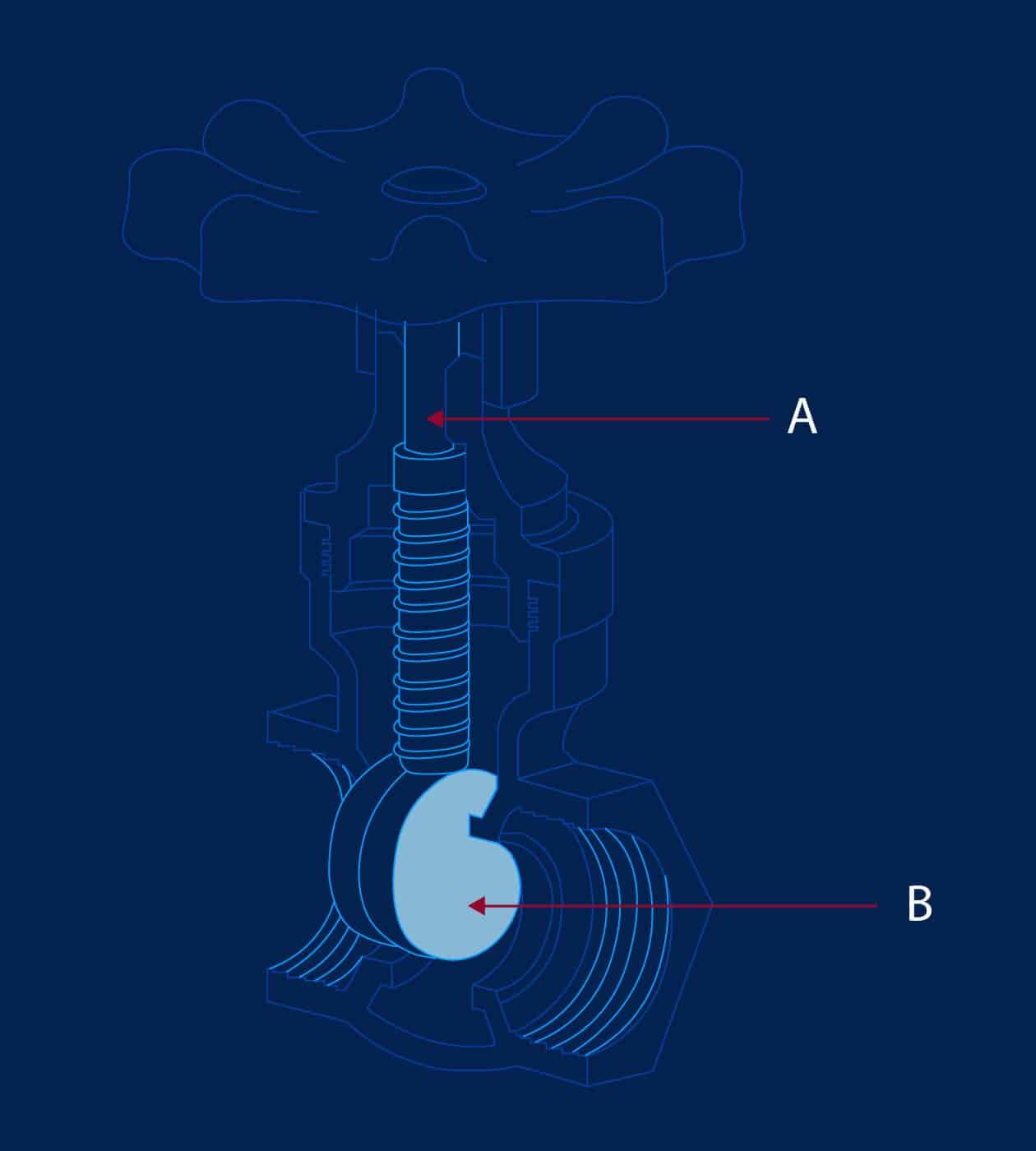

Gate valves consist of a gate or wedge that moves perpendicular to the flow of fluid. This design allows for smooth and uninterrupted flow when the valve is fully open. Gate valves are typically larger and heavier than ball valves, making them less suitable for applications with limited space.

Ball Valve Design

Ball valves feature a spherical disc with a hole through the center, which aligns with the flow path when the valve is open. The quarter-turn operation of ball valves makes them ideal for applications requiring rapid shutoff. Their compact design also makes them easier to install in confined spaces.

Read also:Who Is Adam Fs Wife A Comprehensive Look Into Their Life And Relationship

Functionality and Operation

The functionality of a valve is determined by its ability to control the flow of fluids effectively. Both gate valves and ball valves have unique operational characteristics that make them suitable for different applications.

Gate Valve Functionality

Gate valves are primarily used for isolation purposes, meaning they are designed to either fully open or fully close the flow of fluid. They are not recommended for throttling applications, as this can lead to wear and tear on the valve components.

Ball Valve Functionality

Ball valves excel in applications requiring rapid shutoff and precise control. Their quarter-turn operation allows for quick and reliable closure, making them ideal for high-pressure and high-temperature applications.

Materials and Durability

The material of a valve affects its durability, resistance to corrosion, and suitability for specific environments. Both gate valves and ball valves are available in a variety of materials to meet the demands of different industries.

Gate Valve Materials

Gate valves are commonly made from materials such as stainless steel, bronze, and cast iron. These materials provide excellent corrosion resistance and durability, making gate valves suitable for use in harsh environments.

Ball Valve Materials

Ball valves are available in materials such as brass, stainless steel, and PVC. The choice of material depends on the application requirements, with stainless steel ball valves being ideal for high-pressure and high-temperature applications.

Cost Comparison

The cost of a valve is influenced by factors such as size, material, and brand. While both gate valves and ball valves are widely used, their costs can vary significantly depending on these factors.

Gate Valve Cost

Gate valves are generally more expensive than ball valves due to their larger size and heavier construction. However, their cost-effectiveness is often justified by their longevity and reliability in specific applications.

Ball Valve Cost

Ball valves are typically more affordable than gate valves, especially in smaller sizes. Their compact design and ease of installation also contribute to lower overall costs.

Applications and Industries

Both gate valves and ball valves are used in a wide range of industries, but their applications differ based on their unique characteristics.

Gate Valve Applications

Gate valves are commonly used in industries such as water treatment, oil and gas, and power generation. They are ideal for applications requiring infrequent operation and minimal pressure drop.

Ball Valve Applications

Ball valves are widely used in industries such as chemical processing, pharmaceuticals, and HVAC systems. Their quick shutoff capabilities make them suitable for applications where rapid control is necessary.

Maintenance Requirements

Regular maintenance is essential to ensure the longevity and reliability of any valve. Both gate valves and ball valves require specific maintenance practices to maintain optimal performance.

Gate Valve Maintenance

Gate valves should be inspected regularly for signs of wear and tear, especially in the stem and seat areas. Lubrication of the stem and gland packing is also necessary to prevent seizing.

Ball Valve Maintenance

Ball valves require less maintenance than gate valves due to their simpler design. However, regular inspection of the ball and seat for signs of wear is still necessary to ensure reliable operation.

Performance Metrics

Performance metrics such as pressure rating, temperature range, and flow capacity are critical factors to consider when selecting a valve. Both gate valves and ball valves have different performance characteristics that make them suitable for specific applications.

Gate Valve Performance

Gate valves are designed to handle high-pressure and high-temperature applications, making them ideal for use in power plants and oil refineries. Their straight-through flow path also ensures minimal pressure drop.

Ball Valve Performance

Ball valves are known for their excellent shutoff capabilities and are capable of handling high-pressure and high-temperature applications. Their compact design also allows for higher flow capacity in smaller sizes.

Longevity and Reliability

The longevity and reliability of a valve depend on factors such as material, application, and maintenance practices. Both gate valves and ball valves are designed to provide years of reliable service if properly maintained.

Gate Valve Longevity

Gate valves are known for their durability and can last for many years with proper maintenance. Their robust construction and resistance to wear make them ideal for long-term use in demanding applications.

Ball Valve Longevity

Ball valves are highly reliable and can last for decades with minimal maintenance. Their simple design and resistance to corrosion make them suitable for use in harsh environments.

Conclusion and Final Thoughts

In conclusion, the choice between a gate valve and a ball valve depends on the specific requirements of your application. Gate valves are ideal for applications requiring minimal pressure drop and infrequent operation, while ball valves excel in applications requiring rapid shutoff and precise control.

We encourage you to leave a comment or share this article with others who may find it helpful. If you have any questions or need further clarification, feel free to reach out to us. Additionally, explore our other articles for more insights into industrial piping systems and valve technology.

References:

- ASME B16.34 - Valve Standards

- API 6D - Pipeline and Piping Valves

- ISO 14313 - Petroleum, Petrochemical, and Natural Gas Industries