In today's competitive business environment, supplier development has become a critical strategy for companies aiming to enhance their supply chain performance and achieve long-term success. By investing in supplier development, organizations can build stronger relationships with their suppliers, improve product quality, reduce costs, and foster innovation. This strategic approach not only benefits the buying organization but also empowers suppliers to grow and thrive in an increasingly complex marketplace.

Supplier development involves a collaborative effort between buyers and suppliers to improve the capabilities of the supplier base. It focuses on enhancing supplier performance, increasing efficiency, and aligning supplier goals with those of the buying organization. This process is essential for businesses looking to stay ahead in their industries and deliver superior value to customers.

As businesses continue to expand globally, the need for effective supplier development programs has never been more important. In this comprehensive guide, we will explore the key aspects of supplier development, its benefits, strategies for implementation, and best practices. By the end of this article, you will have a clear understanding of how supplier development can drive growth and create value for your organization.

Read also:Christopher Hildebrant Cincinnati Profile A Comprehensive Look Into His Life And Achievements

Table of Contents

- What is Supplier Development?

- Importance of Supplier Development

- Benefits of Supplier Development

- Key Components of Supplier Development

- Strategies for Effective Supplier Development

- Challenges in Supplier Development

- Measuring Supplier Development Success

- Tools and Technologies for Supplier Development

- Real-World Examples of Supplier Development

- Future Trends in Supplier Development

What is Supplier Development?

Supplier development refers to the systematic process of working closely with suppliers to improve their capabilities, performance, and overall contribution to the supply chain. This involves providing training, resources, and support to help suppliers enhance their operations, product quality, and delivery processes. The ultimate goal of supplier development is to create a mutually beneficial relationship that drives value for both parties.

Core Principles of Supplier Development

The foundation of supplier development rests on several core principles:

- Collaboration: Encouraging open communication and partnership between buyers and suppliers.

- Continuous Improvement: Focusing on ongoing enhancements in processes, products, and services.

- Shared Goals: Aligning supplier objectives with the strategic priorities of the buying organization.

Importance of Supplier Development

In today's interconnected business world, supplier development plays a crucial role in ensuring supply chain resilience and competitiveness. By investing in supplier development, organizations can address various challenges, such as quality issues, cost inefficiencies, and supply disruptions. Furthermore, it enables companies to tap into the innovation potential of their supplier base, leading to the development of new products and solutions.

Impact on Global Supply Chains

As businesses expand their operations across borders, supplier development becomes even more vital. It helps organizations navigate the complexities of global sourcing while ensuring compliance with local regulations and standards. By fostering strong relationships with international suppliers, companies can secure a competitive edge in the global marketplace.

Benefits of Supplier Development

Implementing a robust supplier development program offers numerous advantages for organizations:

- Improved Quality: Enhanced product quality leads to higher customer satisfaction and reduced returns.

- Cost Savings: Streamlined processes and increased efficiency result in lower costs for both buyers and suppliers.

- Innovation: Collaborative efforts drive the creation of new products and solutions that meet evolving market demands.

- Supplier Retention: Stronger relationships foster loyalty and reduce supplier turnover.

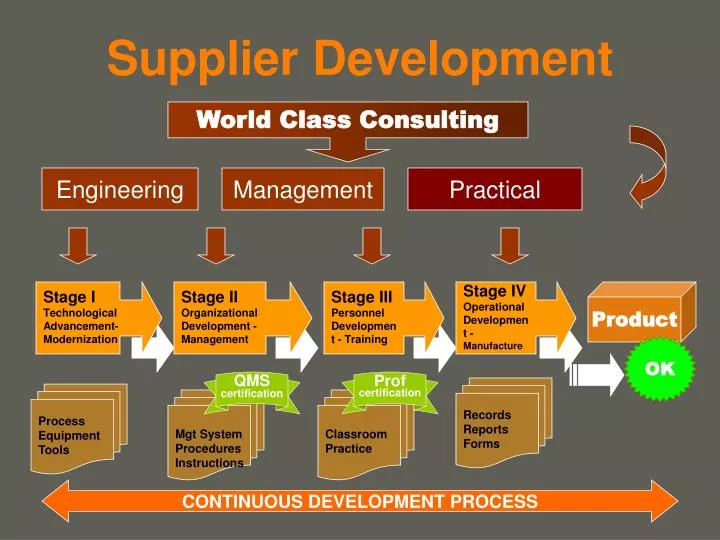

Key Components of Supplier Development

A successful supplier development program consists of several key components:

Read also:Welcome Post On Gravityinternetnet Your Ultimate Guide To Digital Excellence

1. Assessment and Evaluation: Regularly assessing supplier performance and identifying areas for improvement.

2. Training and Development: Providing suppliers with the necessary skills and knowledge to enhance their capabilities.

3. Performance Monitoring: Continuously tracking supplier progress and providing feedback to ensure alignment with goals.

Best Practices for Assessment

When evaluating suppliers, consider the following best practices:

- Set clear performance metrics and benchmarks.

- Conduct regular audits and reviews.

- Encourage open communication and feedback.

Strategies for Effective Supplier Development

Developing a successful supplier development strategy requires a well-thought-out approach. Here are some strategies to consider:

1. Establish Clear Objectives: Define specific goals and expectations for supplier development initiatives.

2. Foster Collaboration: Encourage teamwork and open communication between buyers and suppliers.

3. Invest in Training: Provide suppliers with the resources needed to improve their operations and capabilities.

Building Long-Term Relationships

Creating lasting partnerships with suppliers is essential for sustainable success. Focus on:

- Developing trust and transparency.

- Aligning long-term strategic goals.

- Supporting supplier growth and development.

Challenges in Supplier Development

Despite its numerous benefits, supplier development comes with its own set of challenges. Some common obstacles include:

- Resistance to Change: Suppliers may be reluctant to adopt new processes or technologies.

- Resource Constraints: Limited budgets and personnel can hinder the effectiveness of development programs.

- Cultural Differences: Global operations may encounter cultural barriers that affect collaboration.

Overcoming Resistance

To address resistance, focus on:

- Communicating the benefits of development initiatives.

- Providing incentives for participation.

- Offering tailored support to meet individual supplier needs.

Measuring Supplier Development Success

Evaluating the effectiveness of supplier development programs is critical for ensuring their success. Key performance indicators (KPIs) to consider include:

- Quality Improvement: Track reductions in defects and returns.

- Cost Reductions: Measure savings achieved through process improvements.

- Supplier Satisfaction: Assess supplier feedback and engagement levels.

Using Data Analytics

Data analytics can play a significant role in measuring supplier development success. By leveraging advanced analytics tools, organizations can gain deeper insights into supplier performance and identify areas for improvement.

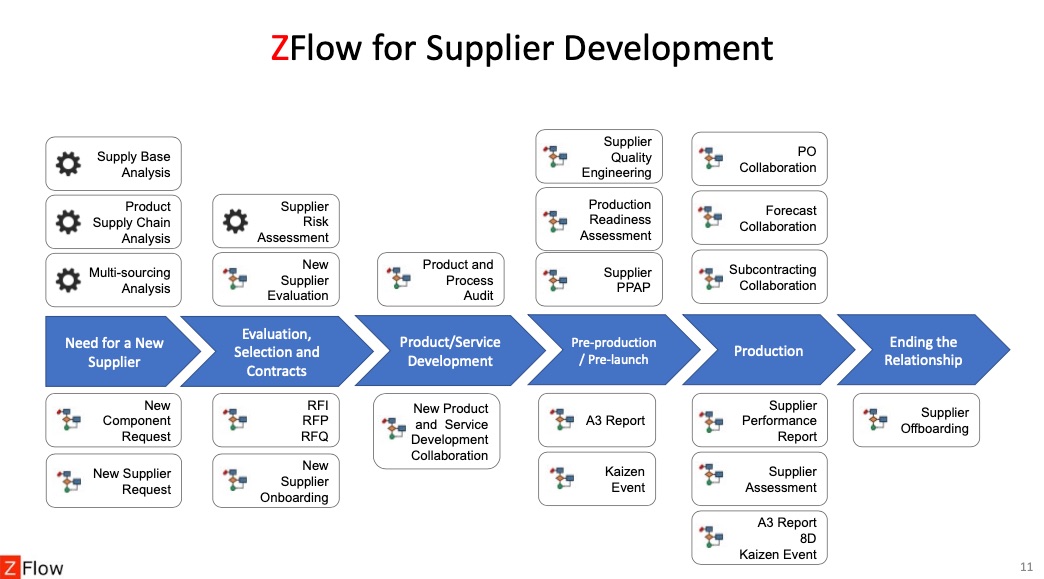

Tools and Technologies for Supplier Development

Several tools and technologies can enhance supplier development efforts:

- Supply Chain Management Software: Streamlines communication and collaboration between buyers and suppliers.

- Learning Management Systems: Facilitates training and development programs for suppliers.

- Performance Tracking Platforms: Enables real-time monitoring of supplier progress and performance.

Real-World Examples of Supplier Development

Many leading companies have successfully implemented supplier development programs. For instance:

Toyota: Toyota's Supplier Support Center provides training and resources to help suppliers improve their operations and meet the automaker's high standards.

Apple: Apple's Supplier Responsibility program focuses on enhancing supplier capabilities and promoting ethical practices throughout its supply chain.

Lessons from Industry Leaders

By studying successful supplier development initiatives, organizations can learn valuable lessons:

- Invest in long-term relationships and collaboration.

- Provide ongoing support and resources for supplier growth.

- Measure and evaluate program effectiveness regularly.

Future Trends in Supplier Development

The future of supplier development is shaped by emerging trends and technologies. Some key trends to watch include:

- Digital Transformation: Adoption of digital tools to enhance supplier collaboration and communication.

- Sustainability: Increasing focus on environmentally friendly practices and responsible sourcing.

- Artificial Intelligence: Use of AI to optimize supply chain operations and improve supplier performance.

Preparing for the Future

To stay ahead in supplier development, organizations should:

- Embrace new technologies and innovations.

- Prioritize sustainability and ethical practices.

- Continuously adapt to changing market conditions and customer demands.

Conclusion

Supplier development is a powerful strategy for enhancing supply chain performance and driving business growth. By investing in supplier capabilities, organizations can achieve numerous benefits, including improved quality, cost savings, and innovation. To succeed in supplier development, it is essential to establish clear objectives, foster collaboration, and measure program effectiveness regularly.

We encourage you to take action by implementing supplier development initiatives within your organization. Share your thoughts and experiences in the comments below, and don't forget to explore other valuable resources on our website. Together, we can build stronger, more resilient supply chains for the future.